Our production facilities

Zero-emission logistics outbound

Zero-emission distribution by ship

Hub for onward distribution

Refuelling facilities for methanol

Our primary activity is to produce green biomethanol for use as fuel in internal combustion engines and fuel cells (the energy system) and as an ingredient in chemical production processes (the materials system).

Priority markets during the first phase will be the maritime sector – including deep- and short-sea shipping, aquaculture and fishing – and the European chemical industry.

Biomethanol provides a very good replacement for fossil fuels in most maritime applications and in the land-based transport sector.

Methanol represents a highly efficient energy and hydrogen carrier and can be distributed and refuelled as easily as diesel oil and petrol.

This commodity is one of the largest chemical ingredients used by industry worldwide, and derives today almost entirely from fossil or “grey” sources.

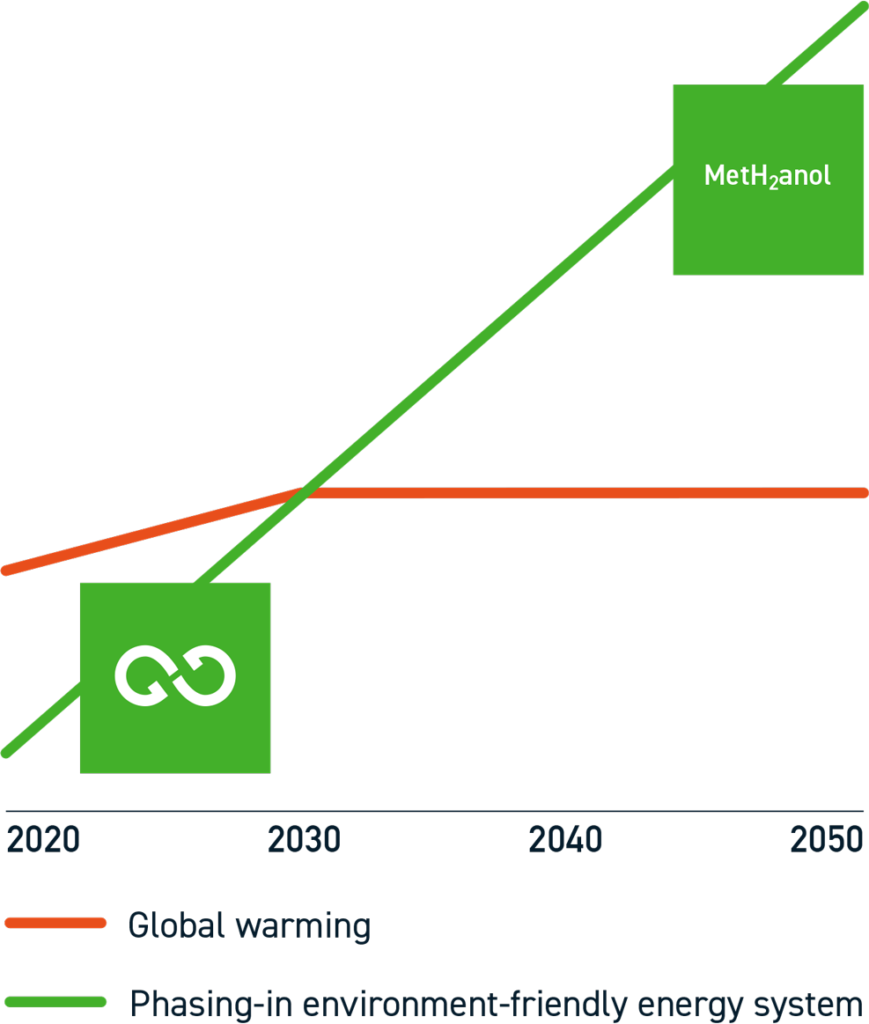

Rapid implementation – slowing down global warming faster Climate changes and the global warm-up are escalating faster than zero-emission solutions can be implemented. Biomethanol can help right now to replace fossil methanol as a fuel for ships and vehicles and as an ingredient in the chemical industry.

Through our Glocal Green Initiative, we want to create a symbiosis between biomethanol, other green methanol and fossil methanol which builds a bridge to phasing-in the environment-friendly versions ¬– as fast as production capacity permits.

This is a question of establishing quicker routes to the end goal, which in turn justifies the means. We will build a fuel-flex system for methanol, where even the fossil version will provide an immediate environmental gain from day one during an introductory phase, compared with using diesel oil.

Chemical industry (the materials system)

Global production of methanol, which amounted to 98 million tonnes in 2020, derives almost entirely from fossil sources.

Most of this output goes to the chemical industry, where it is an important input factor for many other substances and products which the world depends on (such as paint, adhesives and plastics).

Fossil methanol can be replaced only by renewable/green versions.

Deep- and short-sea shipping

Maritime transport accounts for about three per cent of the world’s CO2 emissions. Where deep-sea shipping is concerned, few alternatives to methanol exist after taking account of key factors.

These include practical handling, space requirements, easy refuelling access, retrofitting, and opportunities for rolling out the technology in many shipping segments. In addition, alternatives may present potential explosion hazards, toxicity and leaks of potent greenhouse gases in the event of accidents.

Many players in short-sea shipping are also seeking greener alternatives with greater flexibility owing to the complex and expensive infrastructure requirements of other options, which are not available in many cases.

The ocean sector

Our closeness to and knowledge of the market lay the basis for also introducing solutions for ocean industries. This will be a two-way process, where we can be both a recipient for sludge and a provider of energy solutions.

The ocean sector needs flexible fossil-free energy solutions for use by ships, off-grid fish farms, feed rafts and logistics vessels.

We will here be able to offer green energy solutions based on the fish farmer’s own sludge.

Increased production volumes

Our priority markets lay the basis for substantial production volumes. Combined with an easy-to-complete distribution system for biomethanol/biohydrogen, this will create the foundation for eventual expansion into further market segments. These include long-distance heavy road transport, land-based construction machinery, off-grid electricity generation, data storage centres and, potentially, the small commercial vehicle and passenger car segments – including stationary methanol for electricity charging (Power-to-X) solutions.

Our value chain assessment concentrates on a rational energy transition from fossil sources to green supplies. That creates financially sustainable and durable value chains for residual biological raw materials which have been unutilised so far.

This concept vitalises and re-prices green CO2 resources offered by a multitude of residual biological raw materials and waste. In particular, the opportunity it provides for utilising logging residues (tops and branches) will have a big positive financial impact on the forest industry.

Logging residues represent a huge resource, which is unfortunately left unutilised today in virtually all clearcut areas. They account for no less than 30 per cent of forest biomass, while simultaneously representing an important resource for us.

Glocal Green Initiative

We have established the Global Green Initiative as an association of collaborating partners along the whole value chain. Its purpose is to maximise the utilisation of synergies offered by optimising both environmental and financial sustainability. Such vitalisation will lay the basis for integrated green value chains, both in Norway and internationally.

Establishing production units globally

Our first production unit will be established in Norway in close collaboration with strategic alliance partners. These range from technology suppliers to construction companies and suppliers of residual raw materials from aquaculture, waste management and other biomass production.

Logging residues (tops and branches) from the Norwegian forest industry alone represent about 1.4 million tonnes of available raw material.

This builds on an annual growth rate (measured by commercial timber) in Norway’s forests of about 25 million cubic metres and a harvested volume of roughly 11 million cubic metres.

The first production unit will have an annual production capacity of about 150 000 tonnes of biomethanol, which requires roughly 80 000 tonnes of raw material.

In addition to supplying a strongly growing market for climate-neutral methanol, this initial unit will provide a template for establishing similar production facilities both in Norway and internationally – wherever the availability of sustainable raw materials permits.

Establish complete value chains and direct sales

We will establish complete value chains for biomethanol deliveries to the chemical industry, as fuel for internal combustion engines, and as a hydrogen carrier in fuel cells for the transport sector.

Form alliances with system suppliers

In parallel with developing complete value chains from production to sale of biomethanol, we will create system solutions for using this product as a hydrogen solution in the market.

This work will be pursued through our Glocal Green Energy AS subsidiary and in close collaboration with reformer, fuel cell and other related system/component suppliers.

We are a startup company which expects to grow strongly, and work is under way to build a complete management team. Please contact us if you are interested.

Chief Executive Officer (CEO)

Co-founder.

Long experience as CEO within the seafood industry.

Cand mag., science & business. Company, group and value chain establishments. Long experience from real estate development and management.

+47 926 08 642

dag.nikolai.ryste@glocalgreen.com

Chief Project Officer (CPO)

Long experience from the renewable energy and hydrogen sector. Director general of the Norwegian Hydrogen Association for many years.

Master of European society, science and technology studies, University of Oslo, and BSc in social sciences, University of Bergen.

+47 951 83 350

kristian.vik@glocalgreen.com

Chief Financial Officer (CFO)

Management for hire

More than 20 years experience from management of finance, industry & management consulting. Experience from project, technology and business development, financing, M&A and coordination of companies and projects.

+47 414 71 375

arne.magnus.rise@glocalgreen.com

Chief Sustainability Officer (CSO)

Project manager, Øyer

Hired from Sweco.

Board member and general manager Glocal Green Innlandet AS

Co-founder.

Long experience from leading positions in forestry and wood industry.

Active in education and competence building in the same sectors.

Former director of Gausdal Bruk.

Our board of directors is broad-based, with people drawn from different disciplines.

Acting chairman of the board

Co-founder.

Long experience as CEO within the seafood industry.

Cand mag., science & business. Company, group and value chain establishments. Long experience from real estate development and management.

Board member

Long experience of management in the forest industry and academia. Former CEO of Gausdal Bruk.

Board member

Head of the Maritime Department in the Ministry of Trade and Fisheries 2016-2022. Head of the Section for Internationalization in the Trade Policy Department in the same ministry 2008-2015, and head of the Section for Industrial and Energy Markets in the Norwegian Competition Authority 1999-2007. Has also worked in the Ministry of Petroleum and Energy, Statkraft and NVE. Former board member of INTSOK (Norwegian Oil and Gas Partners).

Cand jur from the University of Oslo and MSc Regulation from the London School of Economics and Political Science.

Board member

Energy advisor in Møre og Romsdal county municipality (end. July 2022). Specialist in hydrogen. International projects. Project manager within district heating. PhD materials technology (NTNU) – carbon nanotubes/structures in cryolite melts. Bachelor of Science in Environment or Resource Technology (NTNU).

Bachelor in environmental technology from the University of Halmstad.

Board member

General manager and administrator in Varde. More than 20 years’ experience from private business in leading positions, both nationally and internationally. Educated economist and engineer, and also has several studies in management. Various other board positions.

Board member

Project Manager Low Carbon Solutions, Equinor ASA. 4 years manager of Equinor’s methanol business. Adm Dir in Statoil Germany 2015 and 2016. Chairman of the Board H2Cluster, various chairman positions in the role of CEO of Statoil Germany, Board member of Statoil Metanol Ans, board member of Tjeldbergodden Luftgassfabrikk. Various other board positions. Several years of experience as a mentor for start-up companies under the auspices of Techstars and the H2 Cluster program.

Board member

Customer support representative in the Norwegian re-use app Tise. Great interest in sustainability and green development.

Bachelor’s degree in international management from BI Business School in Bergen and Esade Business School in Barcelona. Holds significant insight into relevant market criteria after extensive research related to bachelor’s thesis on Glocal Green’s international potential.

Our advisory board is broad-based, and comprises specialists with leading-edge expertise in specific associated disciplines.

Co-founder and owner. Former chemical engineer at Ekornes AS and AkzoNobel. Educated engineer at Oslo Technical College.

Financial Advisor. Long experience as CFO og management in different companies, like Swix og Brav.

Master of Business Administration and auditor education from the University of Agder, Norwegian School of Management in Bergen and George Mason University, Virginia, USA.

Prev. CEO Moelven. Long experience from the wood related industry.