We are in the process of developing our upstream and downstream activities.

That includes working to finance and establish our first production unit in Norway, establish alliances for securing raw materials, customising production and user technologies, and positioning towards various markets.

We are devoting great attention to establishing partnerships with energy and distribution companies which aim to be trendsetters for the green shift in the energy/fuel sector.

In addition, we are establishing direct supplier-customer relations with leading global players in the chemical industry/materials sector.

Input factors for production plants

Our first production unit is due to be established in Norway in close collaboration with strategic alliance partners from the technology, raw materials and marketing sectors.

An expanding consortium is working towards a common environmental and financial goal. Interaction and collaboration have never been more important – or easier.

150 000 tonnes per production unit

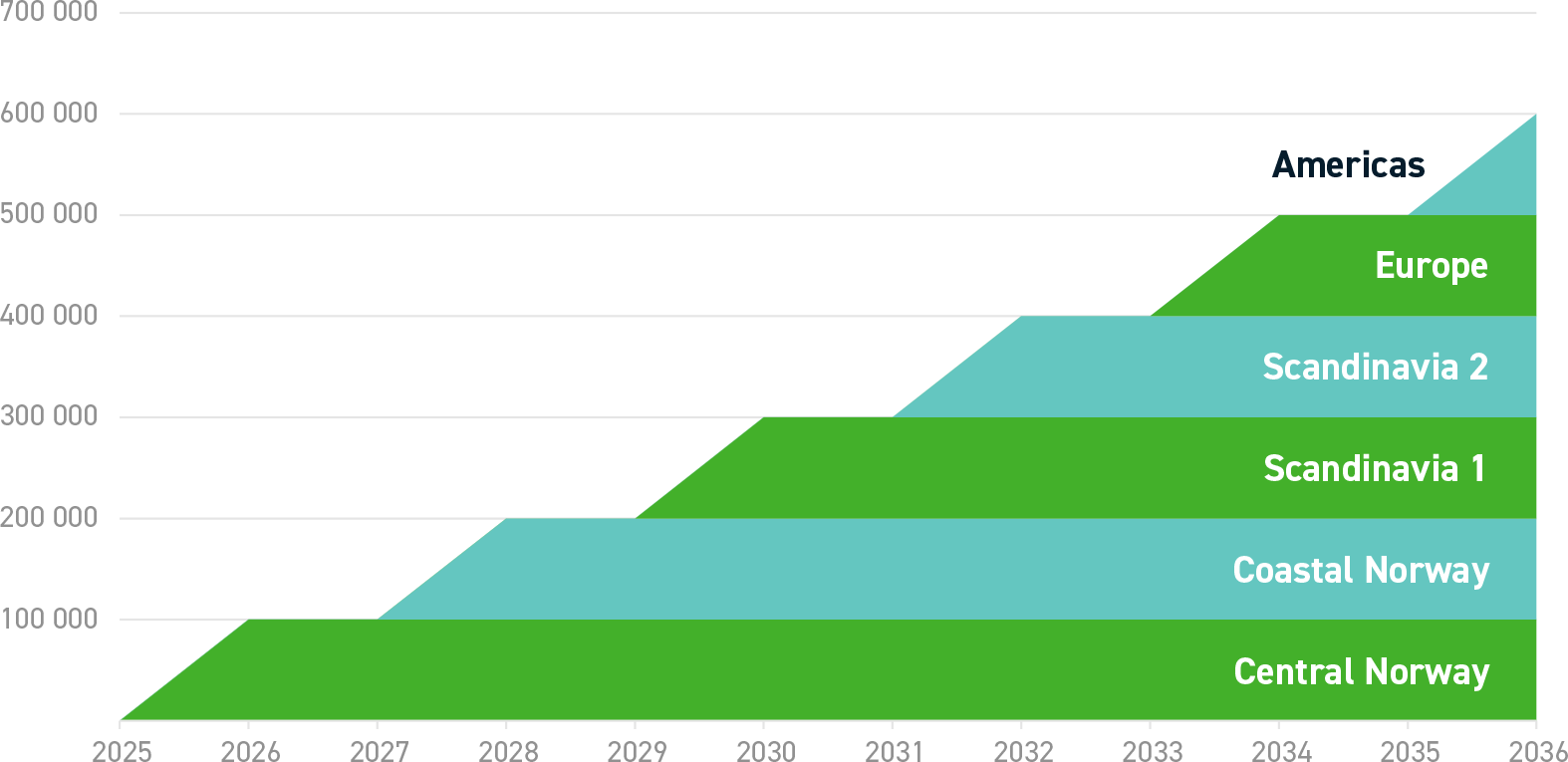

The first production facility being planned at Øyer in east-central Norway will have an annual capacity of about 150 000 tonnes of biomethanol.

This concept is adaptable technologically and has a potential for scaling. That means more production units can be established in Norway and internationally, tailored to raw material availability and access to renewable electricity.

Establish complete value chains and direct sales

We are working to establish complete value chains for biomethanol deliveries to the chemical industry, as fuel for internal combustion engines, and as a hydrogen carrier in fuel cells for the transport sector. The value of a product is measured by its utility, deliverability and predictability.

Form alliances with system suppliers

In parallel with developing complete value chains from production to sale of biomethanol, we will create systems to use this product as a hydrogen solution for the market. That work will be pursued through our Glocal Green Energy AS subsidiary and in close collaboration with various technology and system suppliers.

We are now establishing our first Norwegian production facility in Øyer local authority in Innlandet county, two hours drive north of Oslo.

At the same time, we see the need to develop cases for further locations. Plants could be established in central Norway and along the west Norwegian coast. The choice of sites depends on various factors, including raw material and electric power availability, logistics and collaborative synergies.

Plant capacity may vary, but the optimal starting point targets an annual production of up to 150,000 tonnes. This corresponds to a feedstock requirement of approximately 120,000 tonnes per plant.

The period 2024–2025 has been dedicated to feasibility studies, with more detailed pre-engineering scheduled for 2026. First deliveries of biomethanol from the Norwegian facility are planned around 2030.

We plan to establish several methanol plants with annual delivery capacities of up to 150 000 tonnes. Where conditions permit, each plant will be an optimised hybrid, with gasification, full carbon utilisation and electrolysis to ensure optimum utilisation for each unit of biogenic carbon input as raw material.

Short-travelled, circular and green input factors are naturally preconditions.