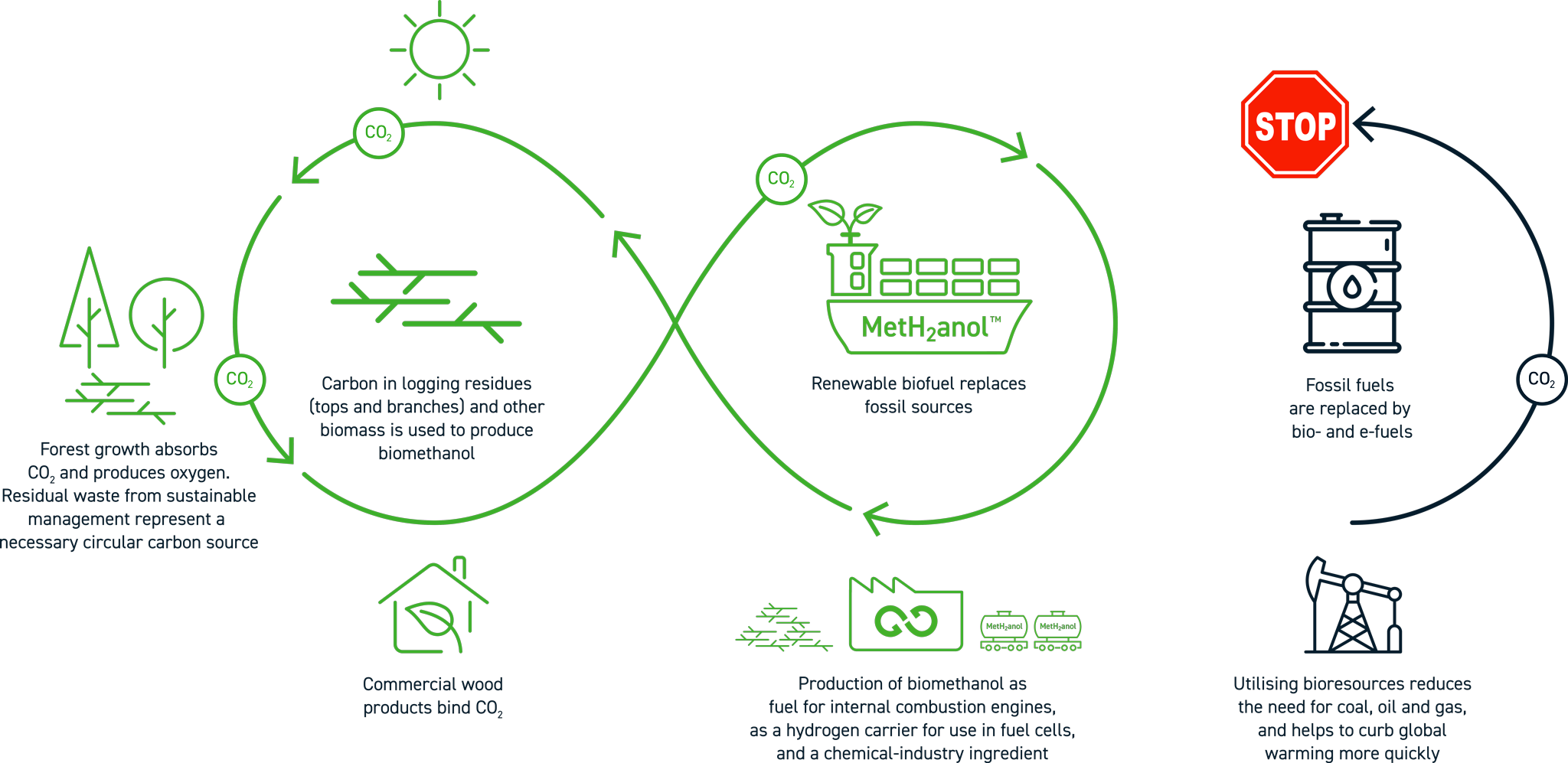

Residual raw materials from sustainable forest management provide a big resource base for our concept.

Annual tree growth in Norwegian forests is currently 200% of the cutting rate.

Leaving logging residues (tops and branches) in clearcut areas to rot down wastes an important green resource and increases the risk of releasing methane (CH4).

The latter is up to 84 times more potent than CO2 as a contributor to climate change.

Exploiting logging residues would facilitate increased replanting and help to improve the economics of Norway’s forest industry.

Removing tops and branches from clearcut areas will facilitate greater replanting. Through photosynthesis, that would in turn enhance total forest biomass and ability to absorb CO2.

Our concept provides a twofold environmental effect – utilising residual renewable raw materials in place of fossil products, while enhancing nature’s ability to slow down the pace of global warming.

Exploiting renewable residual raw materials from wood and other biomass reduces natural biodegradation and emissions of methane and CO2.

This would increase forest absorption of CO2 and thereby nature’s own ability to slow down global warming. The financial and biological sustainability of the forest industry would also improve.

This is a self-fuelled process which exploits the energy in the biomass.

High working temperatures generate steam for gasification and thermal energy for a pyrolysis process in the preheating stage, creating a very energy-efficient and environment-friendly solution.

Methanol is very easy to handle, using virtually the same procedures and technology as diesel oil and petrol.

An existing worldwide energy infrastructure will ensure supplies of biomethanol to the transport sector and the chemical industry.

We see both a clear market need and a resource base for more production units in Norway and internationally.

These would involve a resource-efficient concept based on hybridisation of known technologies, with an envisaged annual methanol output of about 100 000 tonnes per unit.